Introduction to Gear Couplings

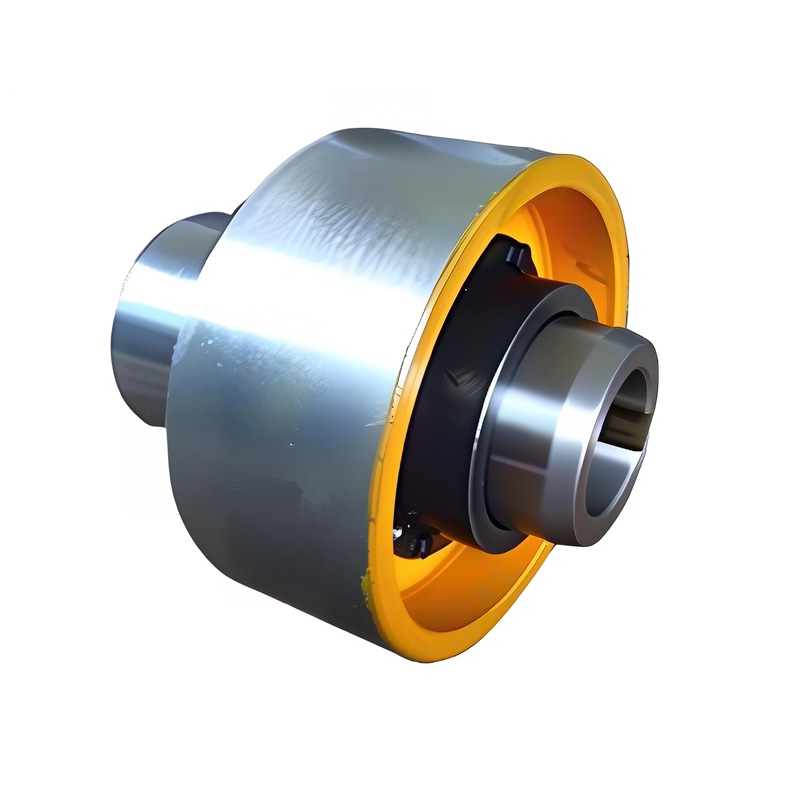

Gear couplings are critical components in mechanical power transmission systems. They are designed to transmit torque and rotational motion between two shafts while accommodating angular misalignments, axial displacements, and radial misalignments. Gear couplings consist of two hubs with internal gears that mesh with external teeth on a sleeve or coupling, making them ideal for industrial applications where precision and reliability are paramount.

Main Applications of Gear Couplings

1. Power Transmission Systems

Gear couplings are commonly used in power transmission systems, particularly in industries such as manufacturing, energy, and automotive. Their ability to handle high torque and misalignment makes them essential in applications where precise synchronization between different components is needed.

- Used in large-scale machinery for efficient power distribution.

- Ideal for high-speed applications that require minimal backlash.

- Ensures smooth and reliable operation of mechanical systems.

2. Industrial Machinery

In industrial machinery, gear couplings play a key role in connecting shafts that drive motors, pumps, and other heavy-duty equipment. They allow for the precise alignment of components while accommodating movement, thermal expansion, and misalignment between connected shafts.

- Provide a secure connection between rotating equipment.

- Reduce maintenance costs by minimizing wear and tear.

- Essential in conveyors, crushers, and mixers for smooth operations.

3. Automotive Applications

In the automotive industry, gear couplings are widely used in drivetrains and axles to transmit rotational motion. Their compact design and ability to handle high torque make them essential for heavy-duty vehicles, including trucks and construction equipment.

- Transmit power efficiently from the engine to the wheels.

- Allow for flexibility in axle design to absorb misalignments and vibrations.

- Used in transfer cases and differential gears for smooth operation.

4. Oil and Gas Industry

In the oil and gas industry, gear couplings are integral in maintaining the performance of drilling rigs, pumps, and compressors. They help to transfer power across multiple components in harsh, high-load environments where reliability is critical.

- Critical for offshore platforms and deep-water drilling systems.

- Provide robust connections between drilling equipment and engines.

- Ensure long-lasting performance even in extreme conditions.

5. Pumps and Compressors

Gear couplings are commonly used in pump and compressor systems, where they help connect rotating shafts to motor-driven components. Their ability to accommodate misalignment and reduce vibration enhances the performance and longevity of such systems.

- Used in industrial water pumps, hydraulic systems, and air compressors.

- Reduce mechanical wear and prevent system failures.

- Provide a reliable connection under high-pressure and high-flow conditions.

Benefits of Using Gear Couplings

Gear couplings provide several advantages that make them highly desirable in various industrial applications:

- Highly effective at transmitting high torque while compensating for misalignments.

- Durable and capable of operating in extreme environments such as high temperatures, pressures, and corrosive conditions.

- Require minimal maintenance due to their robust design and ability to reduce friction and wear.

- Compact and versatile, making them suitable for space-constrained applications.

Conclusion

Gear couplings are a versatile and essential component in a wide range of industrial applications. Their ability to transmit power reliably, accommodate misalignments, and operate under harsh conditions makes them invaluable in industries such as manufacturing, automotive, oil and gas, and more. As industrial demands grow and evolve, gear couplings will continue to play a critical role in the efficient operation of complex mechanical systems.

English

English русский

русский