-

Constant Velocity(CV) JointConstant Velocity Joints (CVJs) for industrial machines transmit power between angled shafts smooth

-

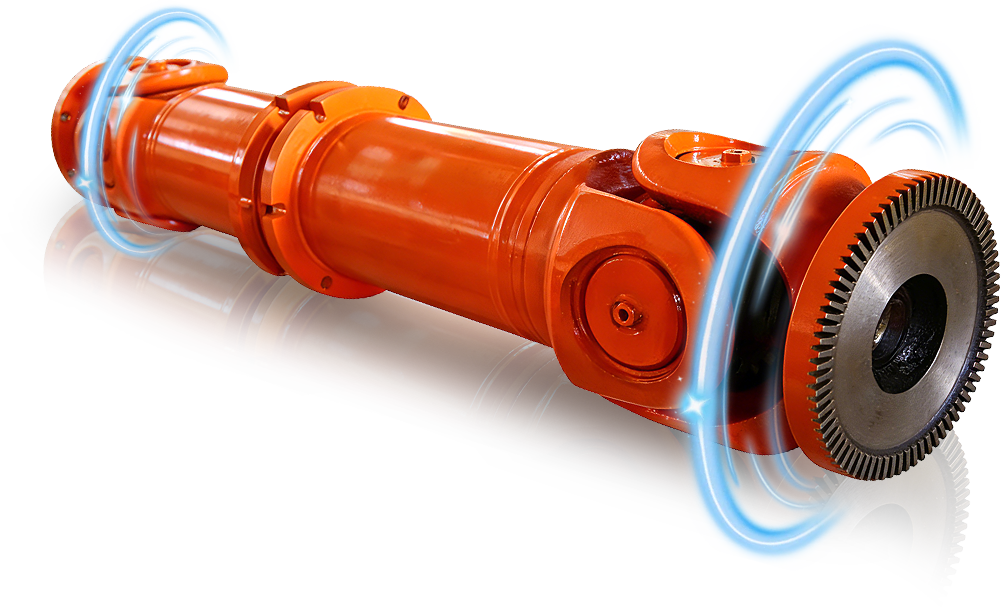

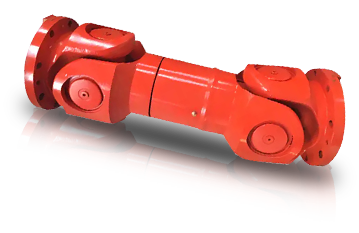

Cardan ShaftsA Cardan shaft, or driveshaft, is a mechanical component that transmits torque and rotational power

-

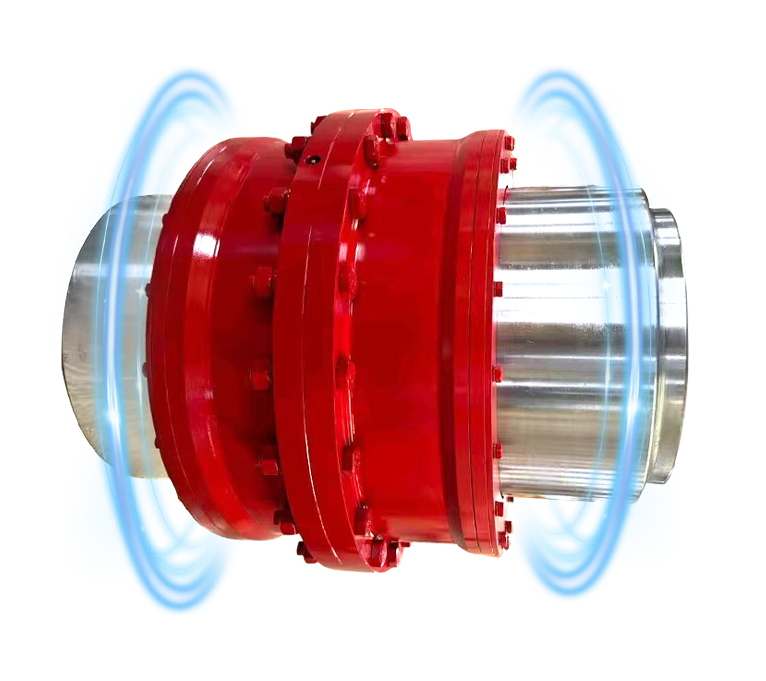

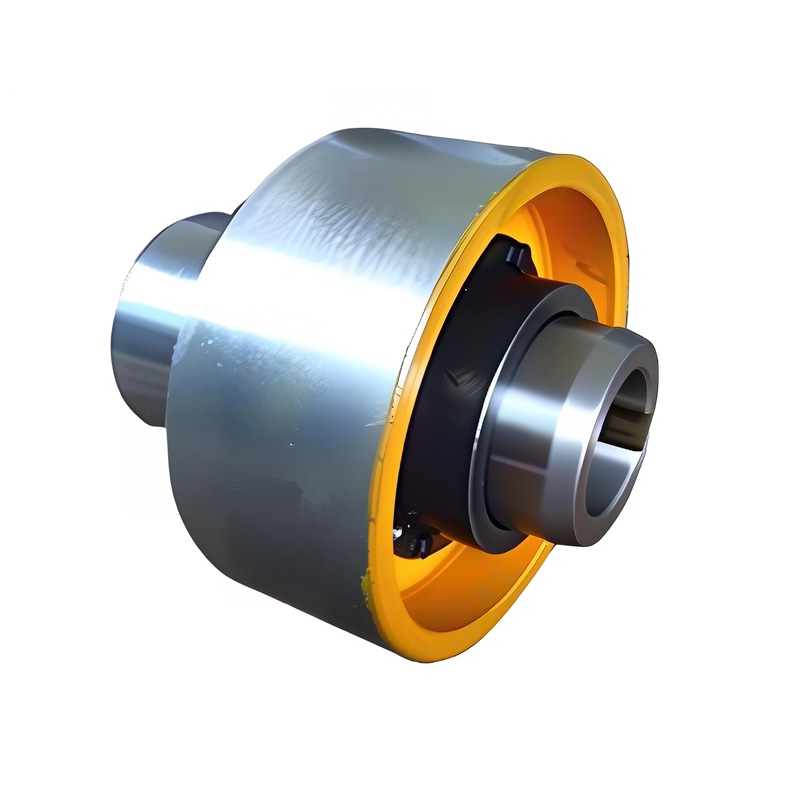

Gear CouplingsA gear coupling is a high-torque mechanical connector for non-collinear shafts, using internal/exte

-

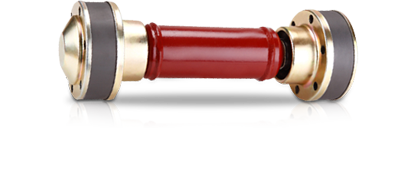

High Speed Diaphragm CouplingsA high-speed diaphragm coupling is a wear-free, maintenance-free mechanical connector for shafts

-

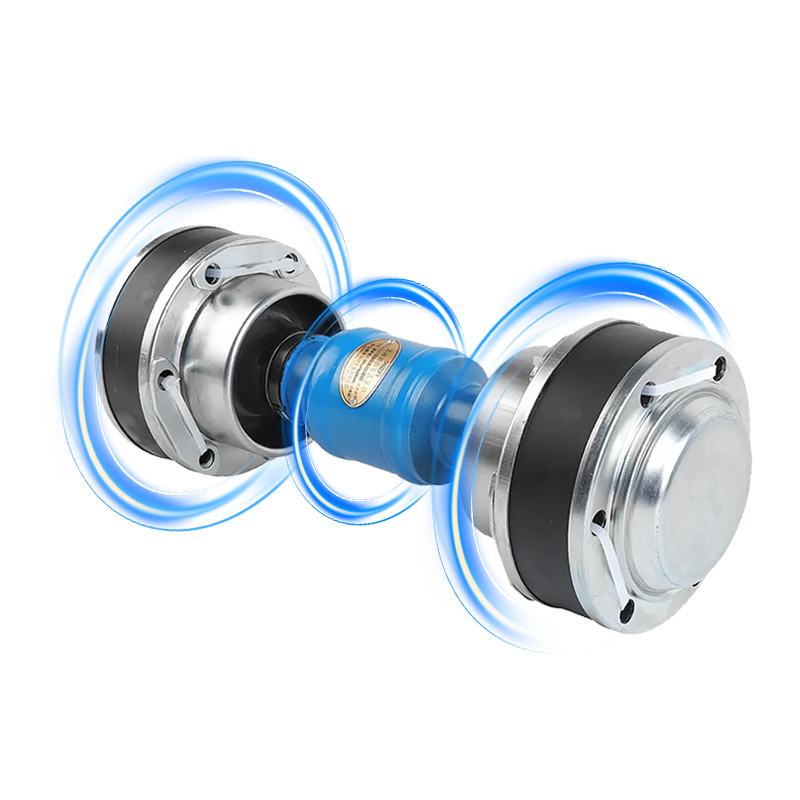

Servo CouplingsA servo coupling connects a servo motor to a machine component, transmitting torque with high preci

-

Flexible CouplingsA flexible coupling connects two shafts to transmit torque while compensating for minor misalignmen

-

Chain CouplingsA chain coupling is a robust power transmission device using two sprockets and a double-strand roll

-

Serpentine Spring CouplingA Serpentine Spring Coupling(Snake Spring Coupling) is an advanced, metal flexible coupling that con

-

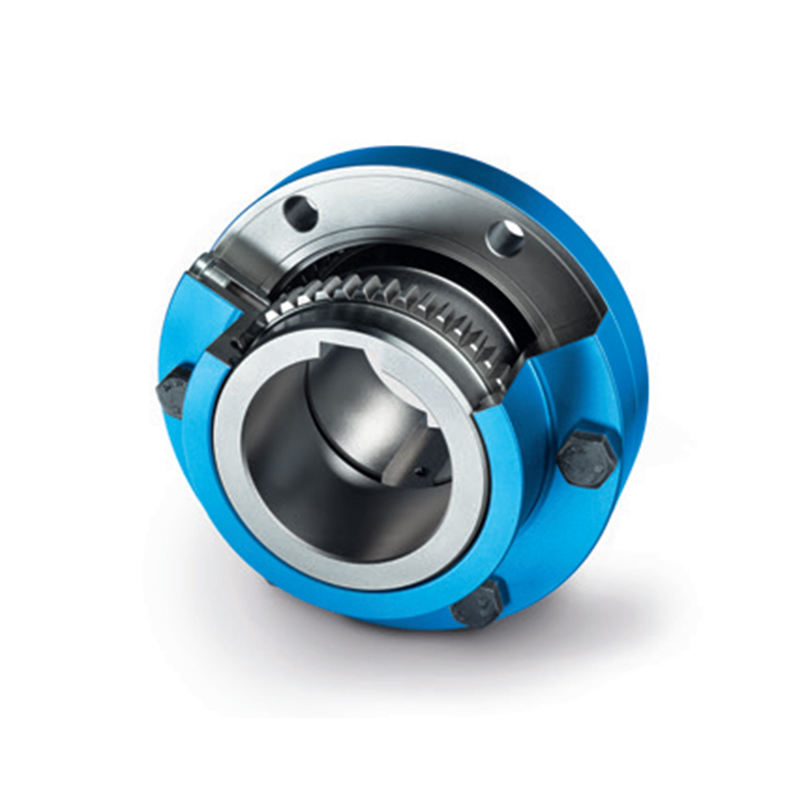

Locking AssemblyA locking assembly is a keyless mechanical device that creates a strong, friction-based connection

-

DIN CouplingsDIN couplings are mechanical shaft connectors manufactured in accordance with German Industrial Stan

MAIN PRODUCTS

Explore Our Products

From product design to manufacturing and distribution, we ensure efficiency, speed, professionalism, and reliability. Our product range primarily covers the following categories of couplings.

ABOUT US

Welcome To Rokang Heavy Industry

Jiangsu Rokang Heavy Industry Technology Co., Ltd.

Rokang is committed to the research and development of ball cage constant velocity universal couplings, drum gear couplings, high-speed diaphragm couplings, wind power couplings, non-standard bearings and cross-axis universal couplings.

Power Transmission Couplings Manufacturers and Suppliers in China.

- 10+

Year's of

experience

CASE

Application Showcase

-

Lithium Battery Expansion EquipmentIn lithium battery electrode rolling equipment, the coupling connects the motor and pressing roller ...View More

-

New Energy Motor Test BenchFor new energy motor test bench, couplings are used to connect the test motor with load equipment or...View More

-

Oil Drilling Rigs and Mud PumpsIn oil drilling rigs and mud pumps, couplings link the drive systems to the drill strings, transmitt...View More

-

MetallurgyIn the metallurgical industry, where harsh environments and fluctuating loads prevail, equipment rel...View More

-

Wind Power GenerationIn the wind power industry, couplings are key components connecting wind turbine systems and directl...View More

-

Special VehiclesRokang Technology designs heavy-duty, high-speed coupling products for specialized vehicles and vess...View More

ADVANTAGES

Why Choose RoKang

-

Service

-

Shipping

-

Capacity

-

Product Diversity

-

Quality

-

Customization

BLOG & NEWS

Our Articles Latest

English

English русский

русский