Clear Definition and Practical Value of DIN Couplings

DIN couplings are standardized mechanical connectors manufactured according to DIN (Deutsches Institut für Normung) specifications. Their primary function is to connect shafts, tubes, hoses, or pipelines in a way that guarantees dimensional accuracy, safety, and interchangeability.

In industrial environments, this standardization translates directly into reduced installation time, fewer compatibility errors, and easier maintenance. When components comply with the same DIN standard, replacement parts from different suppliers can usually be installed without modification.

Why DIN Standards Are Widely Used in Industry

DIN standards are widely adopted across Europe and internationally because they define not only dimensions, but also performance criteria such as pressure limits, tolerances, and testing methods.

- Interchangeability across manufacturers reduces supplier dependency.

- Defined safety margins improve reliability under load and pressure.

- Clear documentation simplifies certification and quality audits.

For sectors such as hydraulics, manufacturing, and energy, DIN couplings are often a baseline requirement rather than an option.

Main Categories of DIN Couplings

DIN couplings are not a single product type but a family of solutions designed for different mechanical and fluid-transfer tasks.

DIN Hydraulic Couplings

These couplings are designed for high-pressure hydraulic systems and are commonly rated between 160 bar and 350 bar, depending on the standard. They allow secure connections while minimizing leakage risks.

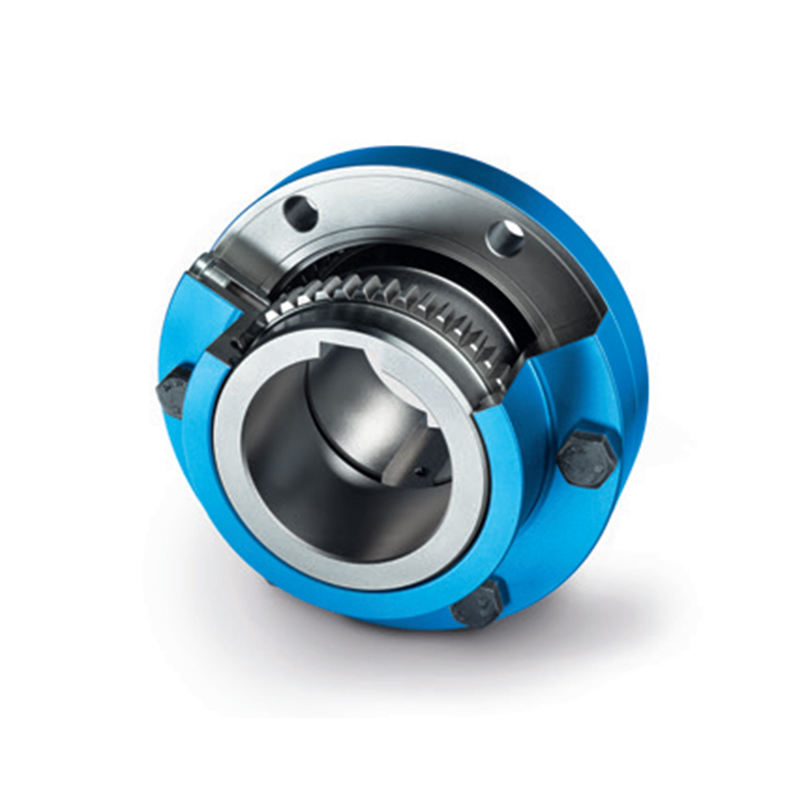

DIN Shaft Couplings

DIN shaft couplings transmit torque between rotating shafts and can compensate for angular, radial, or axial misalignment. Typical applications include pumps, gearboxes, and electric motors.

DIN Hose and Pipe Couplings

These couplings are commonly used in industrial fluid transfer systems, offering standardized sealing and connection geometry. They are widely used in chemical processing, construction equipment, and compressed air systems.

Important DIN Coupling Standards and Their Scope

Each DIN standard addresses a specific coupling design and application range, making correct identification essential.

| DIN Standard | Coupling Category | Typical Industry Use |

|---|---|---|

| DIN 2353 | Hydraulic tube couplings | Hydraulic piping systems |

| DIN EN 14420 | Hose couplings | Bulk fluid and chemical transfer |

| DIN 740 | Shaft couplings | Mechanical power transmission |

Material Choices and Performance Impact

Material selection directly affects durability, corrosion resistance, and operating limits of DIN couplings.

- Carbon steel: high strength and cost-effective for general industrial use.

- Stainless steel: superior corrosion resistance for chemical or outdoor environments.

- Brass: commonly used in low-pressure pneumatic and fluid systems.

Step-by-Step Guidance for Selecting DIN Couplings

Selecting the right DIN coupling should be a structured process based on operating data and compliance requirements.

- Identify the exact DIN standard required by the system design.

- Verify pressure, torque, and temperature limits with a safety margin.

- Confirm material compatibility with fluids and environmental exposure.

- Ensure dimensional compatibility with existing components.

A correctly selected DIN coupling improves system reliability, reduces leakage risk, and lowers long-term maintenance costs.

English

English русский

русский