What Is a Locking Assembly and Why It Matters in Shaft-Hub Connections

A locking assembly is a keyless mechanical fastening device used to create a high-strength, friction-based connection between a shaft and a hub. Unlike traditional keyed connections, it relies on tapered rings and axial clamping force to generate uniform radial pressure, enabling reliable torque transmission without backlash. This makes locking assemblies especially suitable for applications requiring high precision, heavy loads, and long service life.

Working Principle of a Locking Assembly

A locking assembly typically consists of inner and outer conical rings and a set of high-strength screws. When the screws are tightened, the tapered rings are drawn together axially. This movement converts axial force into radial expansion and contraction, producing a uniform 360-degree clamping force between the shaft and hub surfaces.

The resulting frictional connection functions similarly to a shrink fit but without thermal processing. Torque and axial loads are transmitted purely through friction, which significantly reduces stress concentration and improves fatigue resistance.

Practical Advantages Over Keyed Connections

- Eliminates keyways, reducing stress concentration, fretting, and corrosion on shafts and hubs.

- Higher torque transmission capacity compared to conventional keyed joints of the same size.

- Excellent concentricity and repeatable positioning, suitable for high-speed and precision machinery.

- Easy installation and removal without damaging mating components.

Typical Industrial Applications of Locking Assemblies

Locking assemblies are widely used across industries where reliable shaft-hub connections are critical. Common applications include gear mounting, pulley and sprocket fixation, flywheels, brake discs, and drum systems operating under variable loads.

| Industry |

Typical Equipment |

| Metallurgy |

Rolling mills, gear drives |

| Mining |

Conveyors, crushers |

| Engineering Machinery |

Winches, transmission shafts |

Manufacturing Capability Behind Reliable Locking Assemblies

The performance of a locking assembly depends heavily on precision machining, material selection, heat treatment, and quality control. Manufacturers with integrated processing and testing capabilities are better positioned to ensure stable friction coefficients, consistent tolerances, and long-term operational reliability.

Locking Assembly Production and Technical Strength

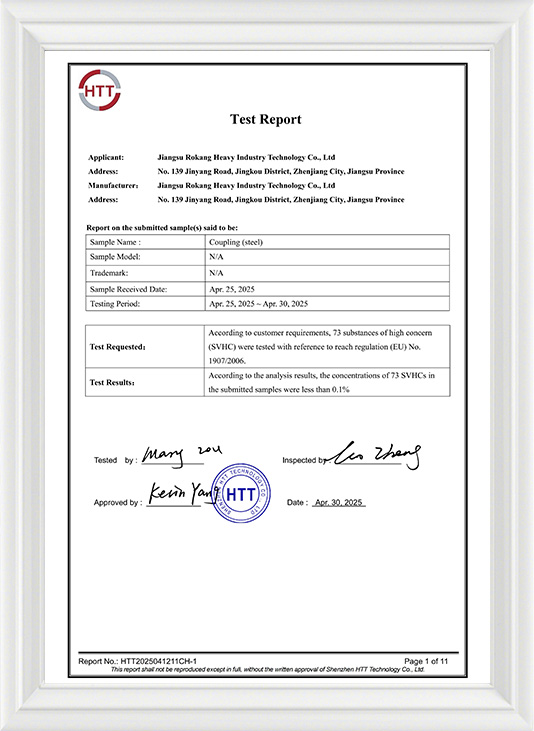

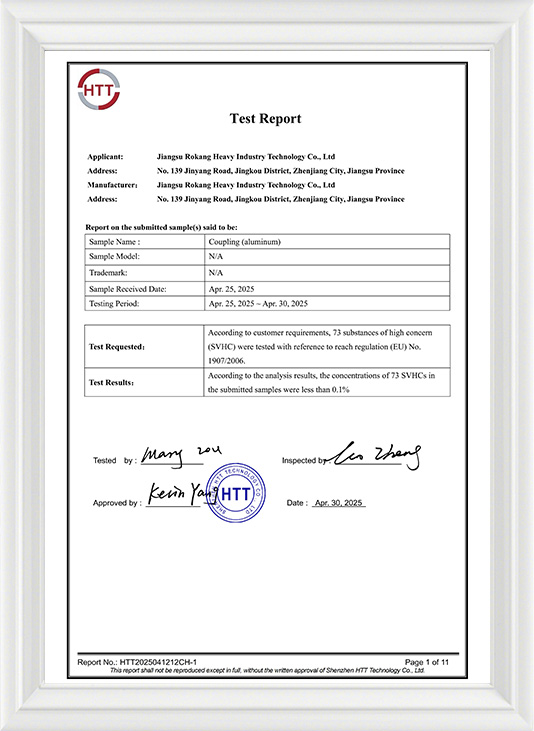

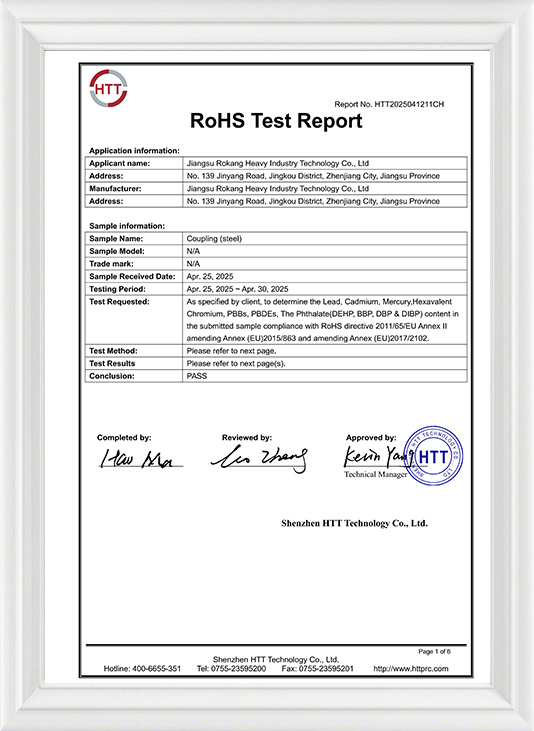

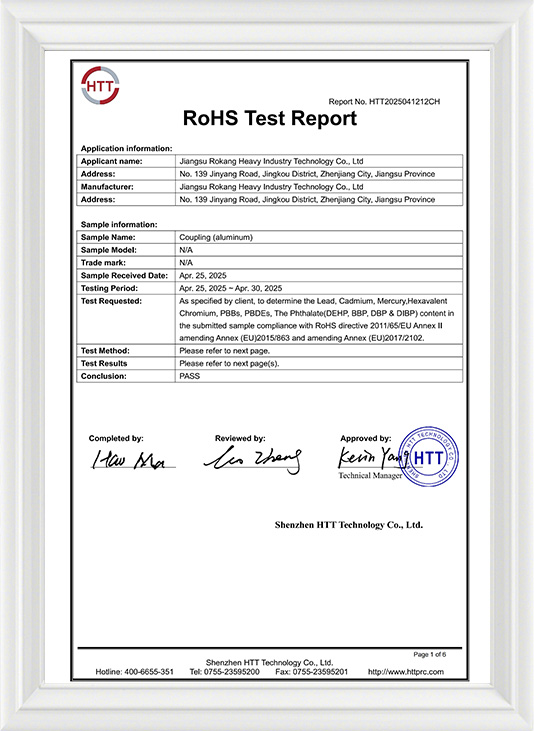

Jiangsu Rokang Heavy Industry Technology Co., Ltd. is a professional locking assembly manufacturer and factory in China with fixed assets exceeding 80 million yuan. The company is supported by a technical team specializing in mechanical design, precision machining, heat treatment, and welding, enabling comprehensive control over the entire production process.

With complete machining facilities and advanced inspection systems covering dimensional measurement, physical and chemical testing, and dynamic performance verification, the company ensures each locking assembly meets demanding industrial requirements.

Application Experience and Industry Recognition

Through long-term cooperation with military and civilian research institutions, the company has continuously expanded into high-precision, heavy-load, and high-speed application fields. Its products are widely used in lifting and conveying equipment, metallurgical machinery, mining machinery, petrochemical systems, textile machinery, railway locomotives, special vehicles, and military equipment.

With proven performance, Rokang’s products have successfully replaced imported brands in many applications and are exported to Europe, the Americas, Russia, the Middle East, and India, earning strong customer recognition for quality and service.

Conclusion: Choosing the Right Locking Assembly Solution

A locking assembly is a practical and reliable solution for modern shaft-hub connections, especially in demanding industrial environments. When combined with strong manufacturing capability, rigorous quality control, and real-world application experience, it delivers long-term performance, safety, and cost efficiency for end users.

English

English русский

русский