A diaphragm coupling for a servo motor connects shafts, transmitting torque precisely while flexing to compensate for minor axial, radial, and angular misalignments, acting as a vital link with low inertia, high torsional rigidity, zero backlash (often), and requiring no lubrication, making it perfect for high-performance servo systems needing accuracy and efficiency.

How it works

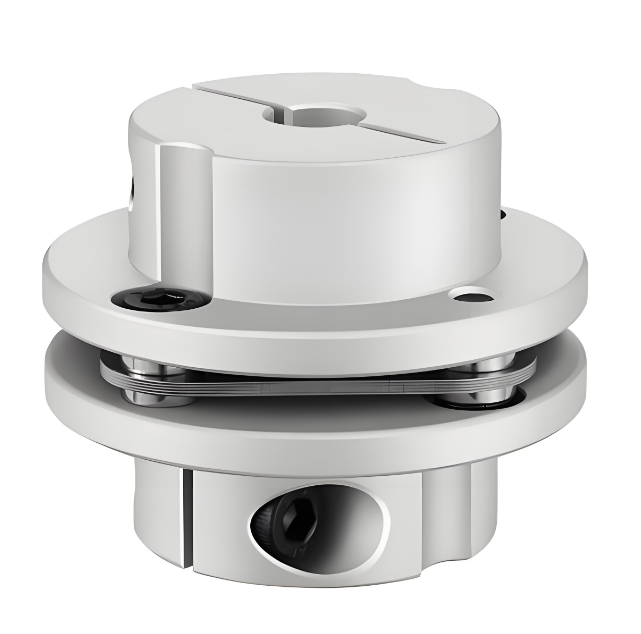

Structure: It uses one or more thin, metallic diaphragms (like flexible metal plates) sandwiched between two hubs or sleeves that connect to the motor and the driven load (like a ball screw).

Torque Transmission: Torque travels from the drive shaft, through the hub, across the flexing diaphragm(s), and to the driven shaft.

Misalignment Compensation: The diaphragm's inherent flexibility allows it to bend and twist, absorbing slight errors in alignment (axial, radial, angular) without stressing the bearings or motor.

Zero Backlash: Many designs use precision-machined components and tight fits (like pinned connections or electron beam welds) to eliminate play (backlash), ensuring precise motion mirroring the servo's commands.

Key advantages in servo systems

Precision: Excellent torque rigidity and zero backlash maintain accuracy.

Efficiency: Low inertia reduces energy loss, ideal for fast-accelerating systems.

Maintenance-Free: No lubrication needed, long life.

Protection: Dampens shock and vibration, protecting sensitive components.

Controlled Failure: Can be designed to fail in a predictable way during severe overload, protecting machinery.

Why it's used with servo motors

Servo motors demand high precision, rapid response, and accurate positioning. Diaphragm couplings provide the stiff, backlash-free connection needed to translate the motor's precise electronic commands into mechanical motion without losing accuracy, making them a preferred choice over general-purpose couplings.

English

English русский

русский