Servo Couplings in Modern Motion Control Systems

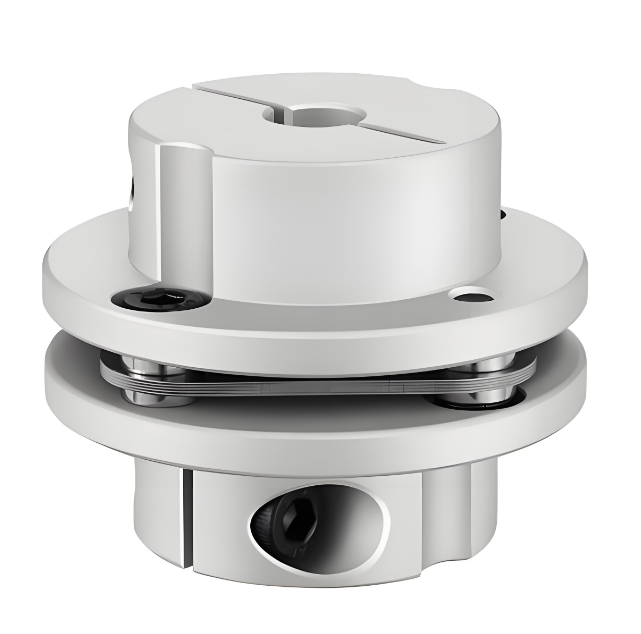

Servo couplings are key mechanical components used to connect servo motors with driven elements such as ball screws, lead screws, gearboxes, or rotary tables. In automation and precision machinery, servo motor couplings play a direct role in converting control commands into accurate mechanical motion. Their design focuses on zero backlash, high torsional stiffness, and low inertia to support fast response and stable positioning.

As automation systems continue to operate at higher speeds with tighter accuracy requirements, the performance of the servo coupling increasingly affects overall system efficiency, repeatability, and service life.

Core Role of a Servo Motor Coupling

A servo motor coupling transfers torque from the motor shaft to the driven component while maintaining precise angular synchronization. Any lost motion or elastic delay in this connection can reduce positioning accuracy, especially in closed-loop control systems.

Servo couplings are therefore engineered to provide a rigid yet flexible connection. They transmit torque efficiently while compensating for small shaft misalignments caused by installation tolerances, thermal expansion, or structural deflection.

Zero Backlash and Positioning Accuracy

Zero backlash is a defining requirement for servo couplings. Backlash introduces delay between motor rotation and driven motion, which can lead to positioning errors, vibration, and control instability.

By eliminating mechanical play through preloaded or elastic transmission elements, servo motor couplings allow direct and predictable response to control signals. This characteristic is essential in CNC machines, robotic joints, and semiconductor equipment where micron-level accuracy is required.

Torsional Stiffness and Dynamic Response

Torsional stiffness defines how much a coupling twists under load. In servo-driven systems, higher torsional stiffness improves dynamic response and helps maintain control accuracy during rapid acceleration and deceleration.

Different servo coupling designs offer varying stiffness levels, allowing engineers to balance rigidity with vibration behavior. Proper selection helps avoid resonance while maintaining smooth and stable motion throughout the operating speed range.

Misalignment Compensation Without Loss of Precision

Even in precision assemblies, perfect shaft alignment is difficult to achieve. Servo couplings are designed to absorb limited angular, parallel, and axial misalignment without transferring excessive forces to motor bearings or driven components.

- Angular misalignment from slight shaft inclination

- Parallel offset due to mounting tolerances

- Axial movement caused by thermal expansion

This controlled flexibility improves system durability while preserving positioning accuracy and repeatability.

Low Moment of Inertia for High-Speed Automation

Low inertia is another critical property of servo motor couplings. Lightweight construction reduces the load reflected to the motor, enabling faster acceleration, deceleration, and direction changes.

In high-speed automation and robotics, minimizing rotational mass directly improves cycle times and energy efficiency while supporting precise control under dynamic conditions.

Different servo applications require different coupling characteristics. Several servo coupling types are commonly used based on stiffness, damping, and misalignment needs.

- Bellows couplings using thin metal bellows to provide high torsional stiffness and zero backlash

- Disc couplings transmitting torque through flexible metal discs with low inertia

- Elastomer or spider couplings offering vibration damping and misalignment tolerance

- Oldham couplings designed for zero backlash and larger parallel misalignment

Application Areas of Servo Motor Couplings

Servo couplings are widely used in industries that rely on accurate and repeatable motion. Their performance directly affects product quality and process stability.

- Industrial robotics and automated assembly systems

- CNC machine tools and high-speed feed drives

- Semiconductor and electronics manufacturing equipment

- Packaging and labeling machinery requiring repeatable motion

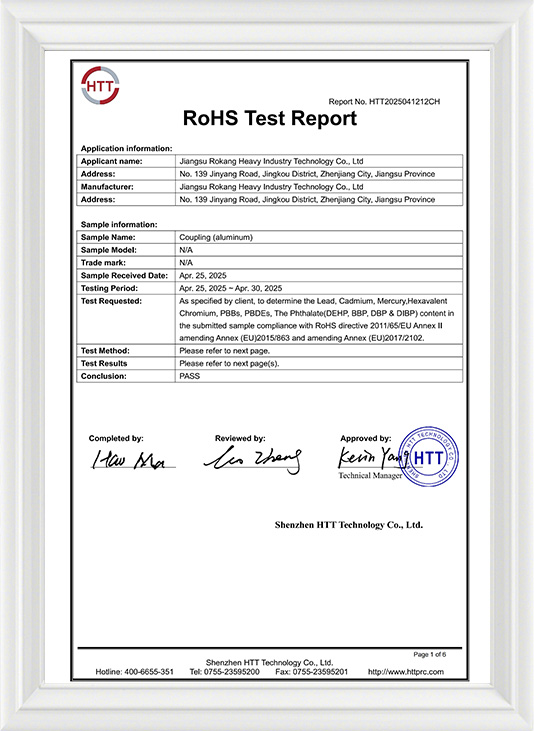

Manufacturing Precision and Engineering Capability

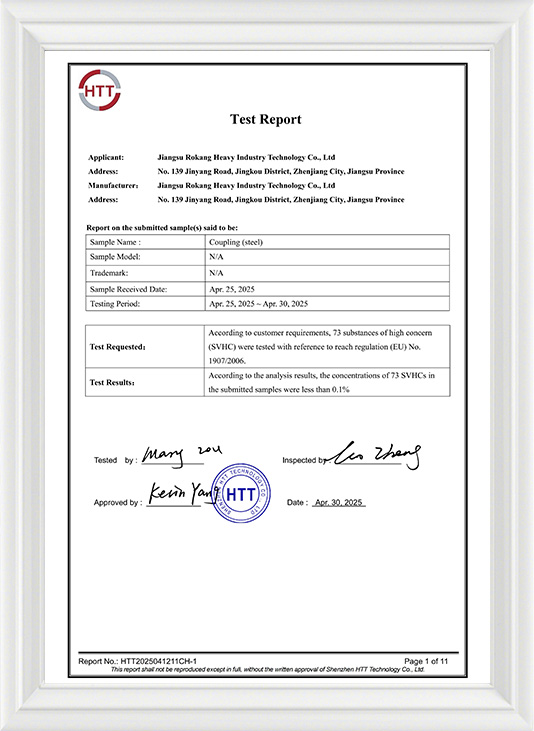

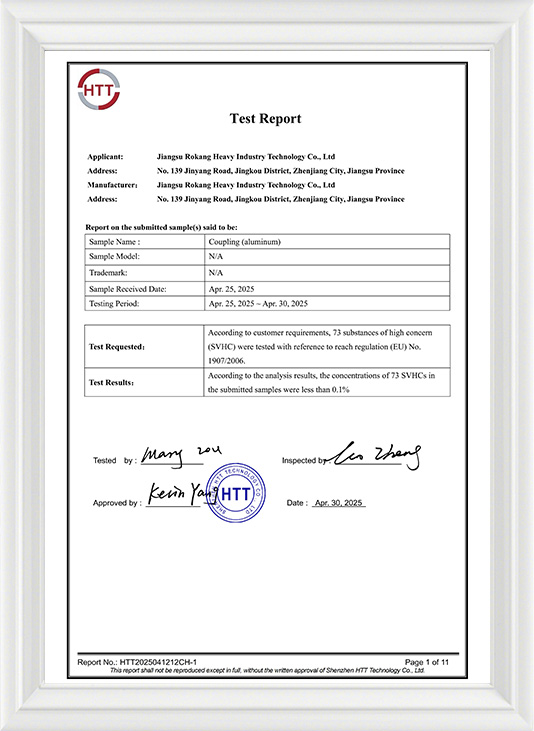

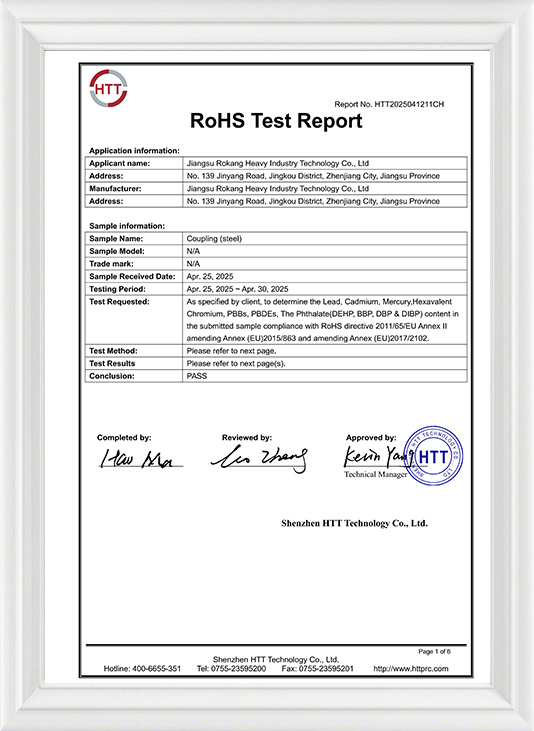

The performance of servo couplings depends heavily on machining accuracy, material selection, and quality control. Tight tolerances and consistent mechanical properties are required to achieve zero backlash and stable stiffness.

With long-term experience in power transmission and coupling technologies, Jiangsu Rokang Heavy Industry Technology Co., Ltd. applies its precision manufacturing and engineering expertise to develop servo coupling solutions suitable for high-accuracy automation and industrial motion control systems.

Conclusion

Servo couplings and servo motor couplings are fundamental components in precision automation. Through zero backlash, controlled torsional stiffness, misalignment compensation, and low inertia, they enable accurate, responsive, and reliable motion control. As automation systems continue to advance, well-designed servo couplings remain essential for achieving high performance and long-term operational stability.

English

English русский

русский